The QuatroPBC machine vision system is constantly evolving to meet the ever-increasing demands of modern manufacturing. While the system initially focused on measuring height and detecting defects, it has now grown into a full-scale tool for comprehensive factory control.

What new features have been added to QuatroPBC — and how can they help streamline your production, making processes more transparent and controlled?

What new features have been added to QuatroPBC — and how can they help streamline your production, making processes more transparent and controlled?

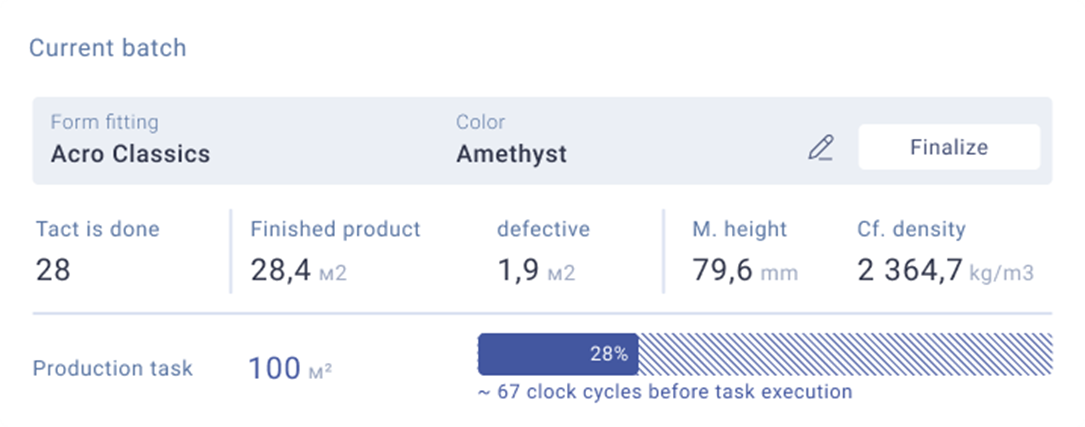

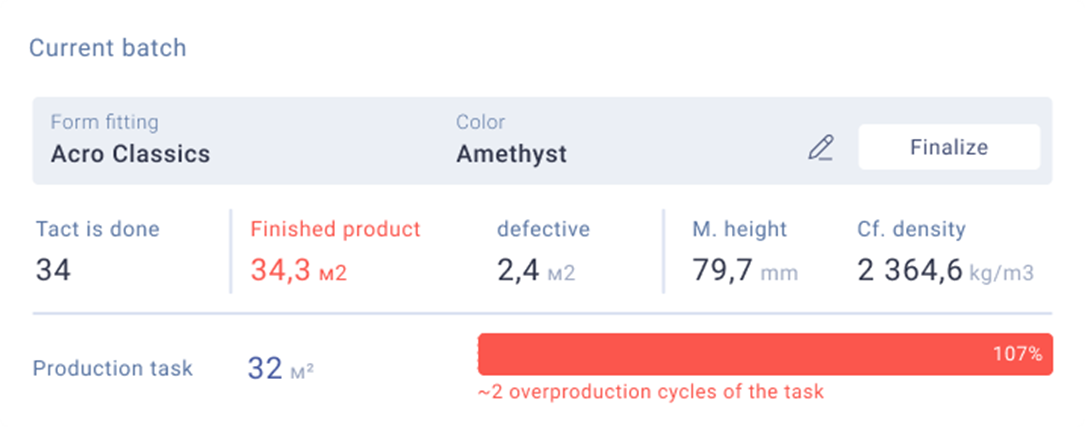

Production task control

In many factories, overproduction of 5–7% is considered the norm. With QuatroPBC, the operator sets the exact number of units to produce and can monitor the process in real-time:

QuatroPBC helps operators meet production goals with precision and helps the plant reduce waste from overproduction. A progress indicator in the interface shows how many cycles are left, whether the task has been completed, and by how many cycles the target was exceeded if the line wasn’t stopped in time.

- Quantity of good products produced (defects excluded)

- How many more units need to be produced

- Any overproduction beyond the original target

QuatroPBC helps operators meet production goals with precision and helps the plant reduce waste from overproduction. A progress indicator in the interface shows how many cycles are left, whether the task has been completed, and by how many cycles the target was exceeded if the line wasn’t stopped in time.

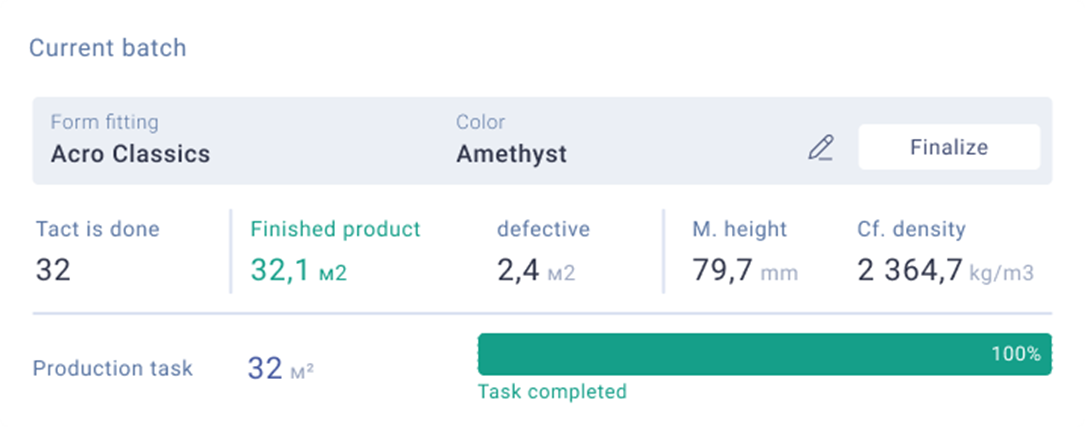

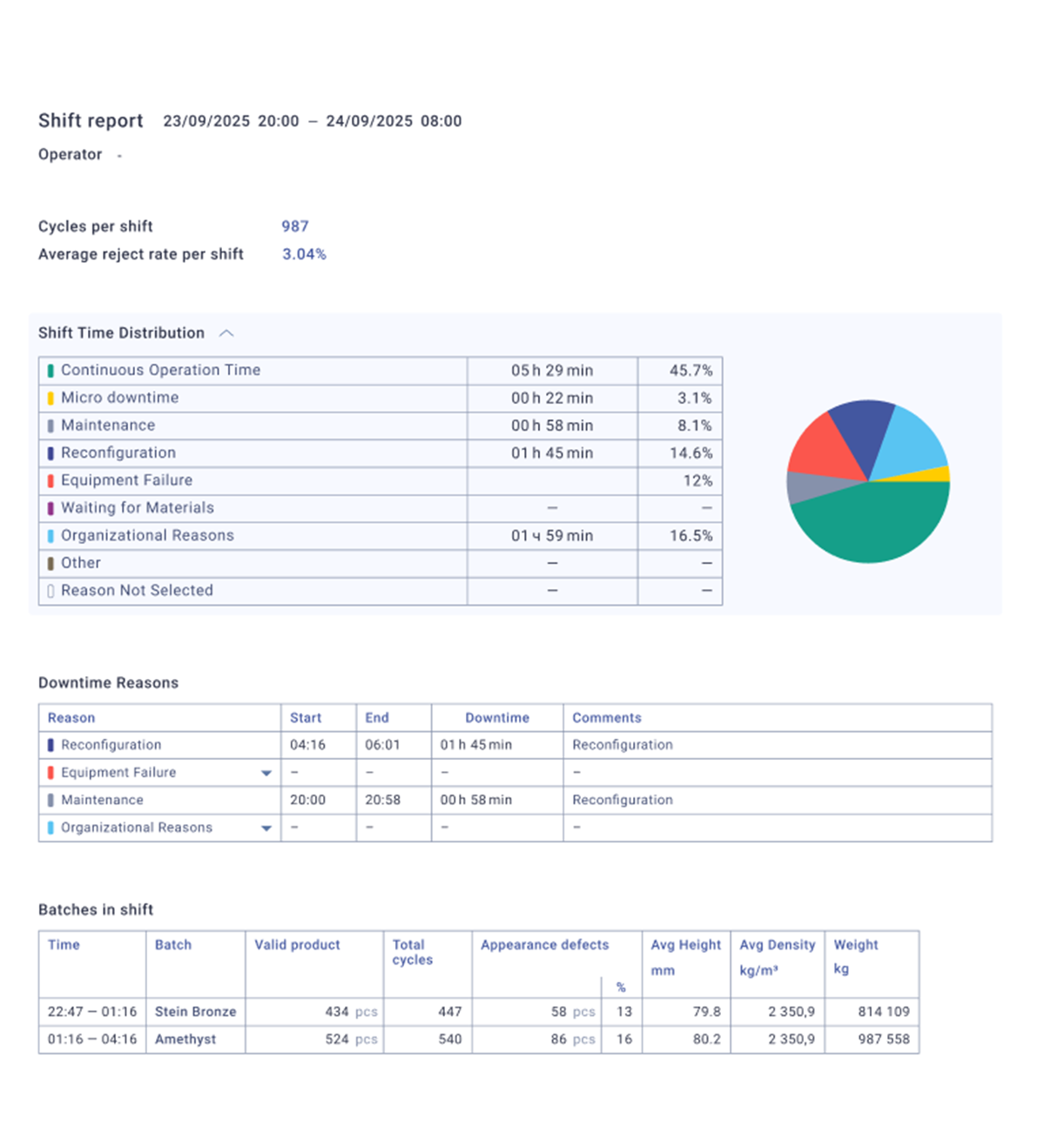

Shift Reports

QuatroPBC automatically generates detailed shift reports that include:

The report can be downloaded as a PDF for review and deeper analysis.

- All downtimes and their types — no stoppage goes unnoticed

- Micro-downtimes — short pauses that can have a big impact on output

- Downtime reasons, with exact timing and causes for further analysis

- Overall performance for the shift

The report can be downloaded as a PDF for review and deeper analysis.

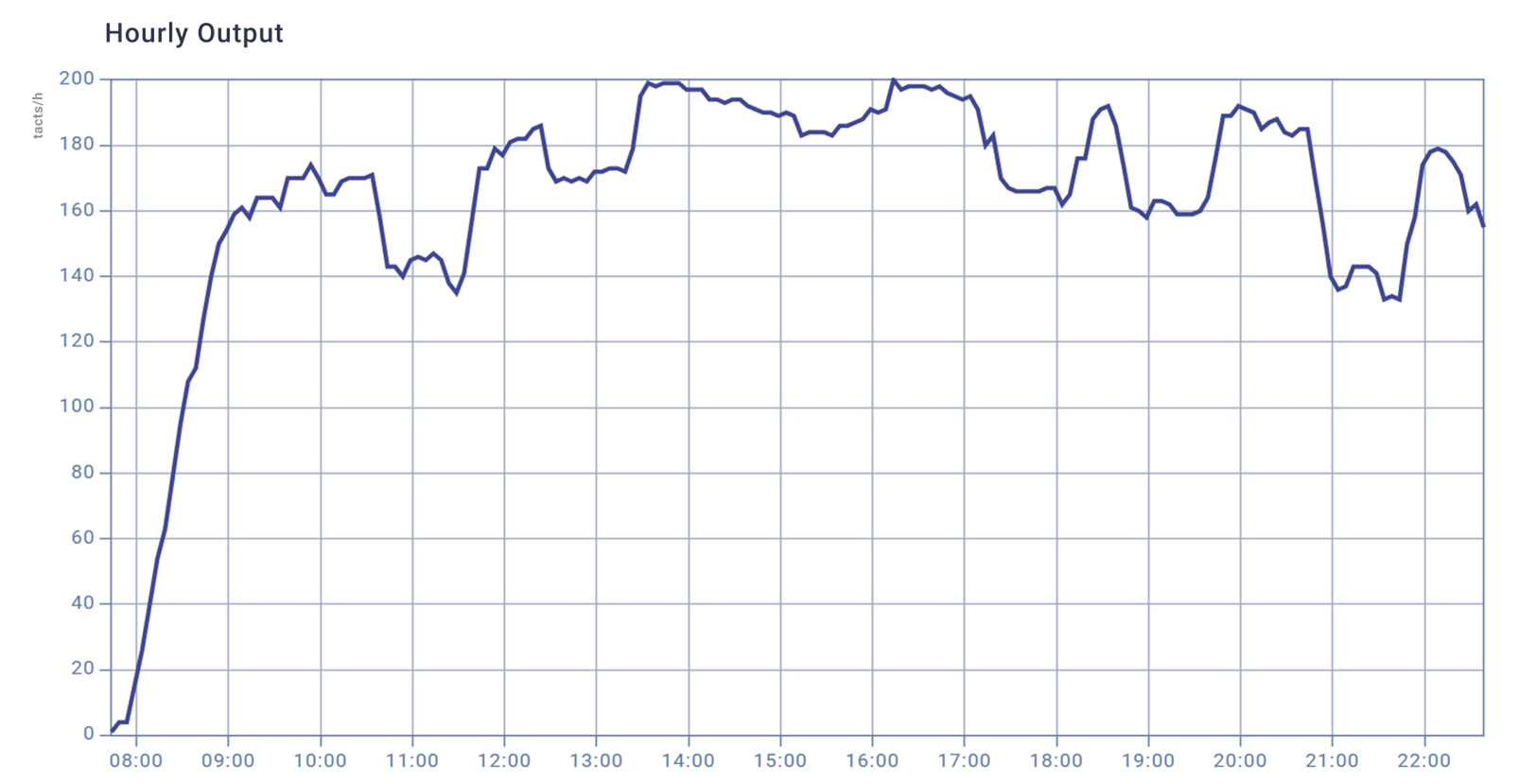

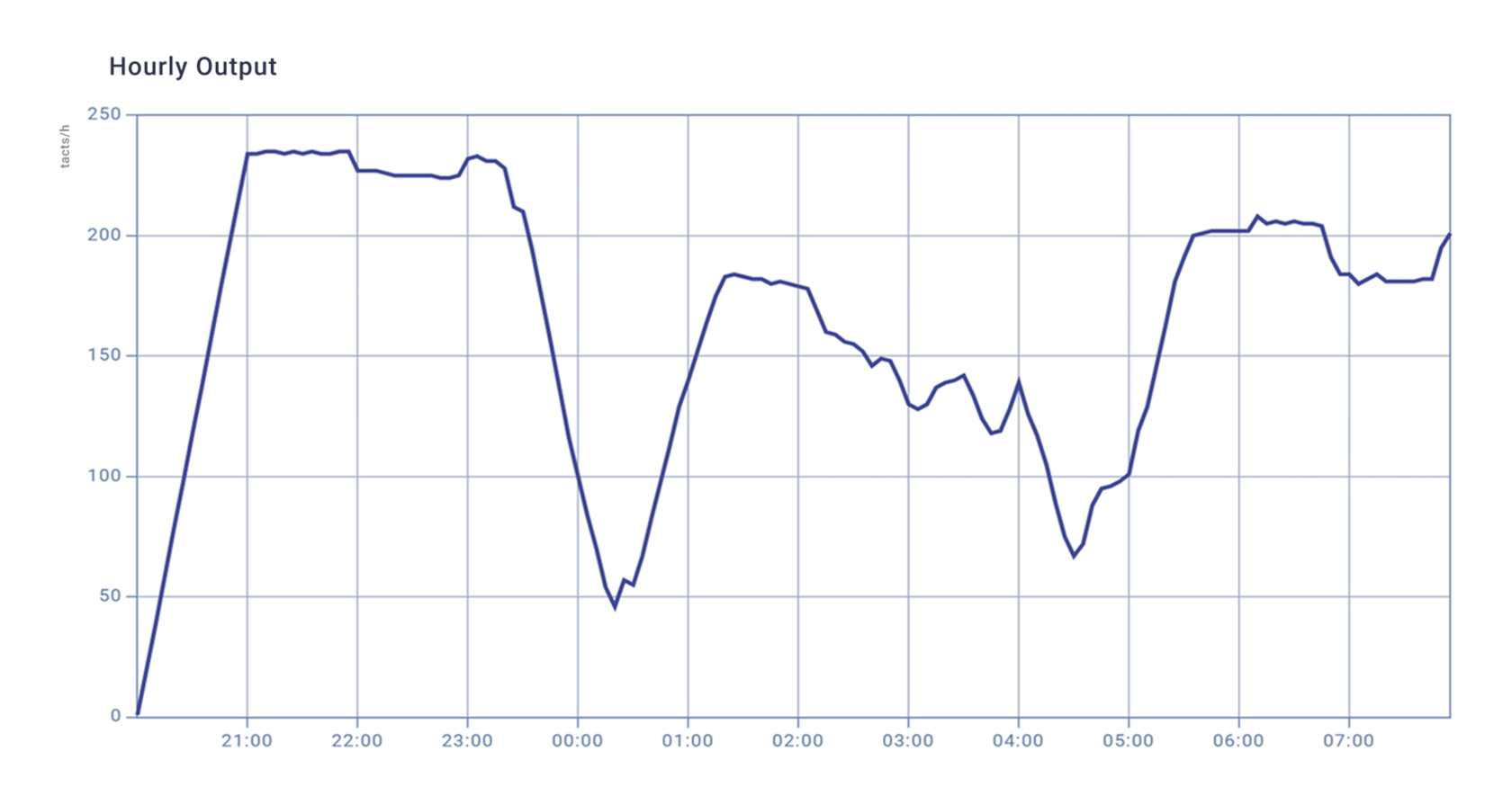

Plant performance is displayed as a graph, allowing you to track peaks in activity and downturns in production by the hour

Example of low shift performance

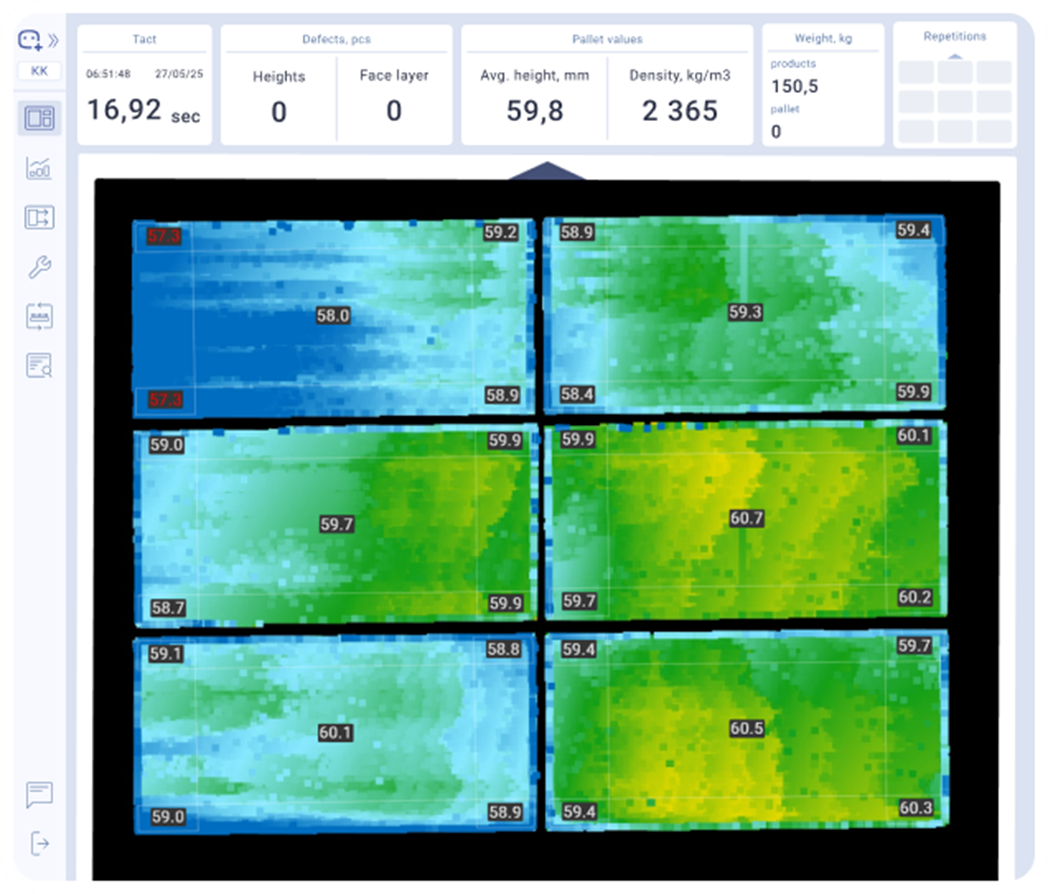

Height Heatmap

The height heatmap function visualizes product height as a color map, making it easy to detect irregularities and calibrate the press in time—helping prevent defective products from being released. With just one glance, the operator can instantly assess whether everything is in order on the pallet.

The color-coded display clearly highlights:

The color-coded display clearly highlights:

- Height excesses

- Height reductions

- Dips and tilts

- Cavities

- Other irregularities

Product height information for the operator

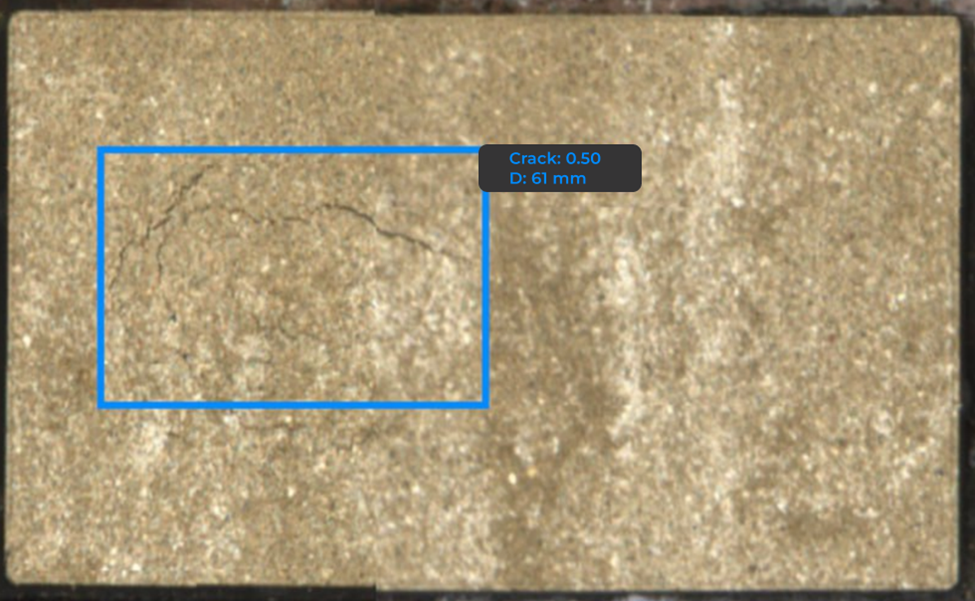

Example of a defective product with a change in height

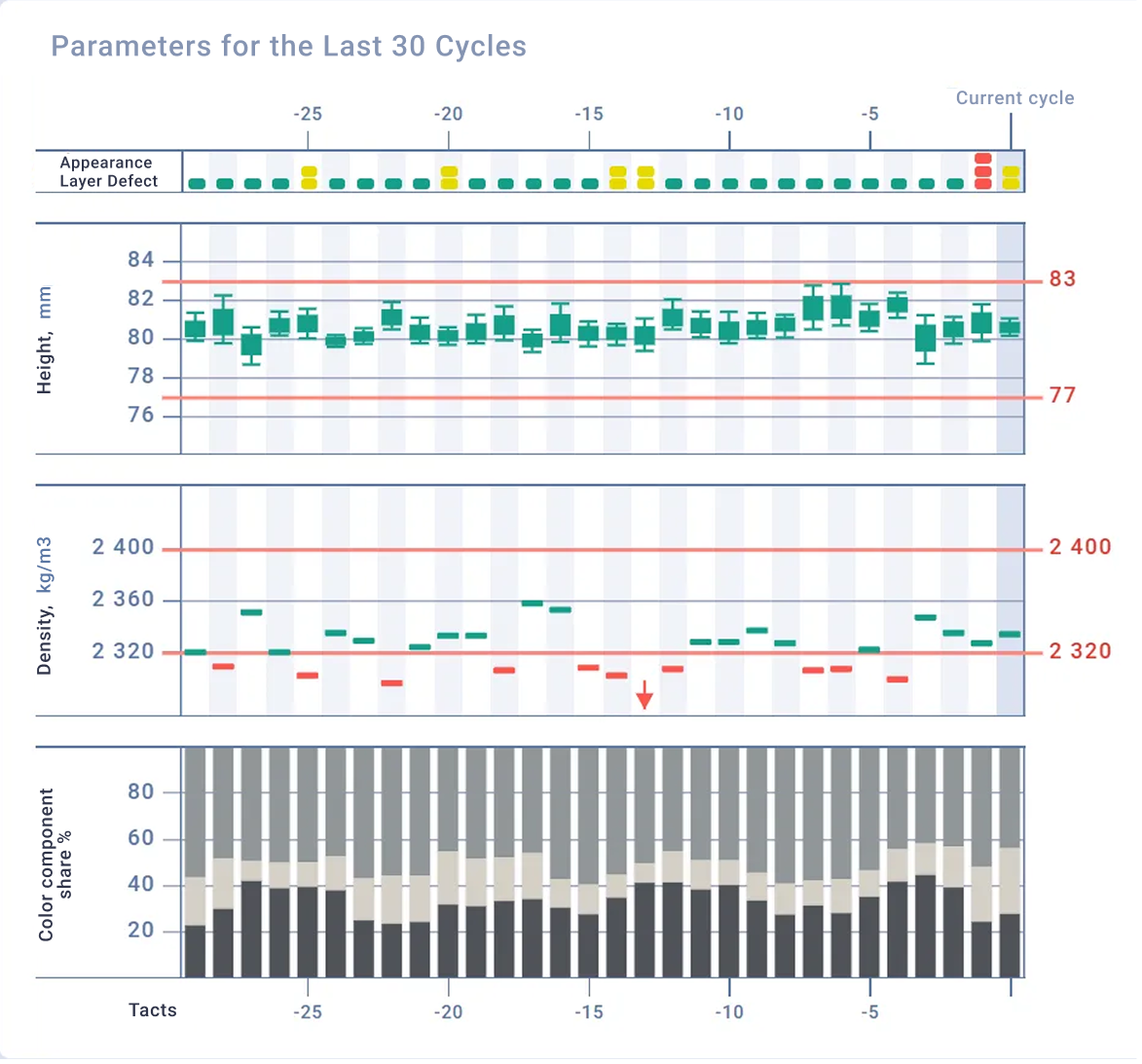

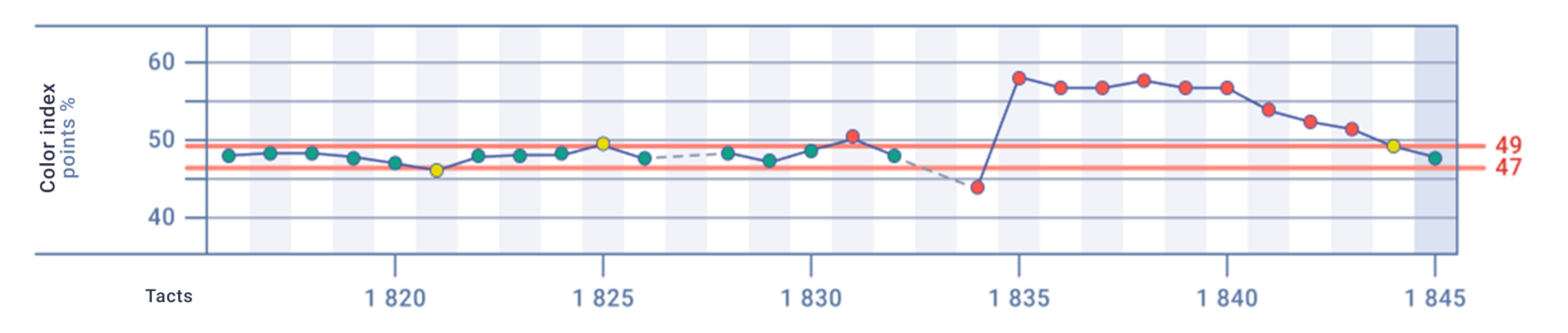

Color Consistency Control

Operators can monitor the consistency of color in real-time — both for single-color products and for multicolor "colormix" tiles.

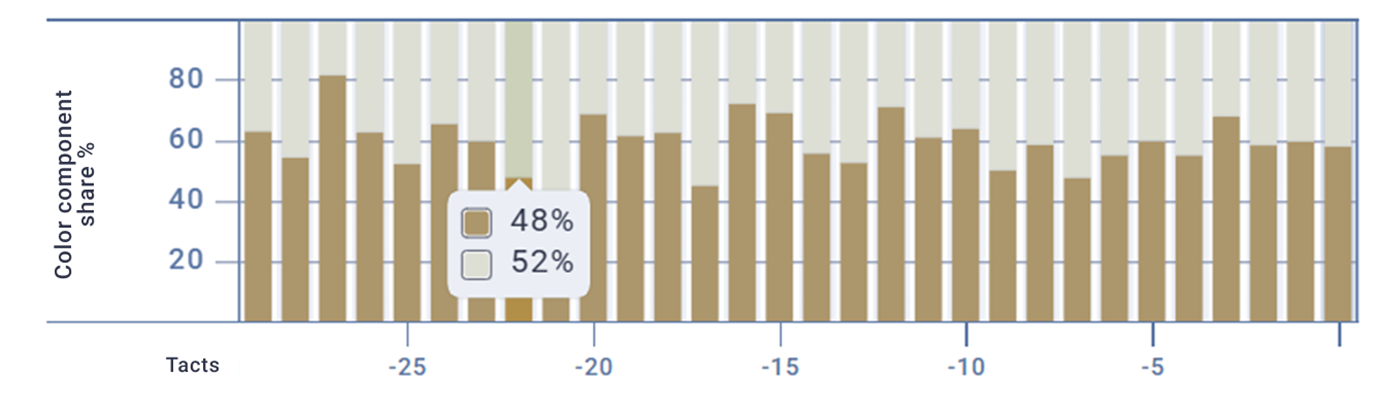

For colored paving, repeatable shade accuracy is crucial. The system ensures stability across batches and analyzes the distribution of color components. This minimizes visible inconsistencies that could affect the perceived quality of your products.

Mono-color stability

Distribution of color mix components

In today’s fast-paced, competitive industrial environment, inefficient resource usage is no longer an option. Every extra kilogram of raw material, every unnoticed defect, and every minute of unplanned downtime represents direct financial loss.

Modern production demands full transparency, accuracy, and control at every stage.

That’s why QuatroPBC is no longer just a useful tool — it’s an essential solution. It provides end-to-end factory control: from defect detection and height measurement (with 0.5 mm precision), to density calculation, color stability monitoring, production order tracking, vibration analysis, and more.

You also get a complete package of analytics and visualizations — including photo archives, automated shift reports, and 24/7 access to all data from any device.

QuatroPBC is your answer to the challenges of high-tech manufacturing — and your confidence in tomorrow

Modern production demands full transparency, accuracy, and control at every stage.

That’s why QuatroPBC is no longer just a useful tool — it’s an essential solution. It provides end-to-end factory control: from defect detection and height measurement (with 0.5 mm precision), to density calculation, color stability monitoring, production order tracking, vibration analysis, and more.

You also get a complete package of analytics and visualizations — including photo archives, automated shift reports, and 24/7 access to all data from any device.

QuatroPBC is your answer to the challenges of high-tech manufacturing — and your confidence in tomorrow