Prevent production

defective products

With automatic wet side defect detection

Get the presentation QuatroPBC

Automate quality control system focused on the pavement industry.

Detects defects in the face layer of bricks such as cracks, holes, inclusions, etc in 95% of cases

Timely detection of defects decreases the production of defective items by up to 80% per year

QuatroPBC

Turnkey solution —

New quality for your production

How does QuatroPBC work?

QuatroPBC is installed on the wet side of the conveyor, after the press, before the curing chamber

01

QuatroPBC scans and takes photos of the production board, detecting deviations in product height or density, as well as repeated defects in the facing layer

02

QuatroPBC scans and takes photos of the production board, detecting deviations in product height or density, as well as repeated defects in the facing layer

02

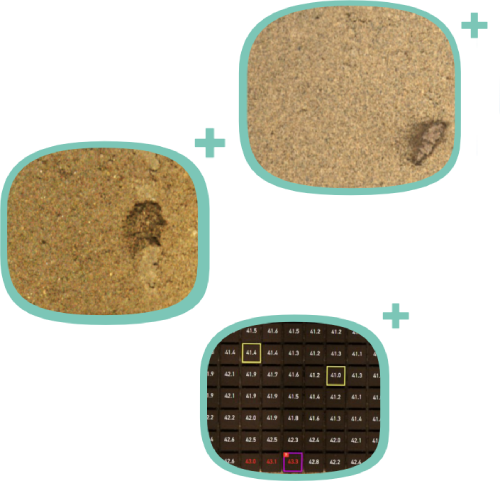

Yellow box -

defective bricks

defective bricks

Visual notification of the operator

Bricks, where defects or height deviations are detected several times in a row on different production board, are additionally highlighted.

Purple box -

repeating defect

the operator needs to pay attention to bricks with defects

Each factory can individually

configured type of recognized defects.

configured type of recognized defects.

Regulation of

flaw detection

FAQ

To detect defects, information about the surface obtained using a laser, as well as conventional camera shots, is used.

The QuatroPBC system is installed on the production line after the press, above the conveyor. The production board passing under the device is non-contact measured by an industrial laser, at the same time, to detect defects in the tile face, 5 cameras simultaneously take a high-resolution photo of each pallet at 35 frames per second.

The resulting photos of all boards are processed using a pre-trained neural network. Every time there is a defect in the image, the network reports it to the operator interface using a color signal. Yellow frame - a tile with a defect, purple - a repeating defect.

The neural network processes photos at a speed of one board of 130 tiles in 2 seconds, which allows you to receive information online and, if necessary, stop the conveyor for further action.

Yes. Now we develop a new approach to determining defects, which is based on determining the type of defects: cracks, holes, and inclusions. Thanks to this approach, the system learns to determine the type, class, and size of the defect. It becomes possible to disable the definition of a defect by class, size, or type.

The procedure for further actions to deal with defective products depends on the regulations of your factory. There are several options for the development of events:

At the moment, the built-in visual warning system in the operator interface helps to prevent the production of defective products. The definition of repeated defects is highlighted with a purple frame on the operator's screen. Determination of stones with a defect - yellow frame.

- The operator can remove defective bricks before or after the curing chamber;

- QuatroPBC will stop the conveyor (for this you need to set up the integration of the quality control system and the production line);

- QuatroPBC will signal the operator to stop the conveyor.

At the moment, the built-in visual warning system in the operator interface helps to prevent the production of defective products. The definition of repeated defects is highlighted with a purple frame on the operator's screen. Determination of stones with a defect - yellow frame.

You can use only the detection function, which includes the collection and visualization of defect statistics. Defect detection is included in the PRO. You can find out more about the PRO version by writing to us at info@quatromatic.com Our manager will provide detailed information

Developed by

Quatromatic

Quatromatic

QuatroPBC is your digital assistant: it works 24/7 and monitors the quality of each product in real-time

Contacts

Get in touch

Сontact us

Stay up to date

Istanbul Office:

Eıs bosphorus dıs ticaret limited sirketi

Address: Maslak Mah. Taşyoncası Sk. Maslak1453 T4A Blok No:1U/B117 Sarıyer/İstanbul, Türkiye

Eıs bosphorus dıs ticaret limited sirketi

Address: Maslak Mah. Taşyoncası Sk. Maslak1453 T4A Blok No:1U/B117 Sarıyer/İstanbul, Türkiye

QUATROMATIC LTD

Company number: 15677742

HEADQUARTERS:

4-8 Ludgate Circus, London, England, EC4M 7LF

Company number: 15677742

HEADQUARTERS:

4-8 Ludgate Circus, London, England, EC4M 7LF