Problems with product color characteristics are the most difficult to detect. Today in the industry this parameter is 100% dependent on the human factor. For this reason, color defects are often detected after the product has been delivered to the customer, and sometimes even after it has been laid (installed). This significantly increases the manufacturer's costs of compensating for this defect, because it is necessary to compensate not only for the loss of material that was used for the production, but also for the costs of delivery and possibly laying (installation).

Thus, color defects have one of the highest processing costs.

Until recently, there was no way to eliminate color defects.

For the first time in the history of the small-piece concrete industry, there is a continuous measuring instrument capable of ensuring high-quality color characteristics.

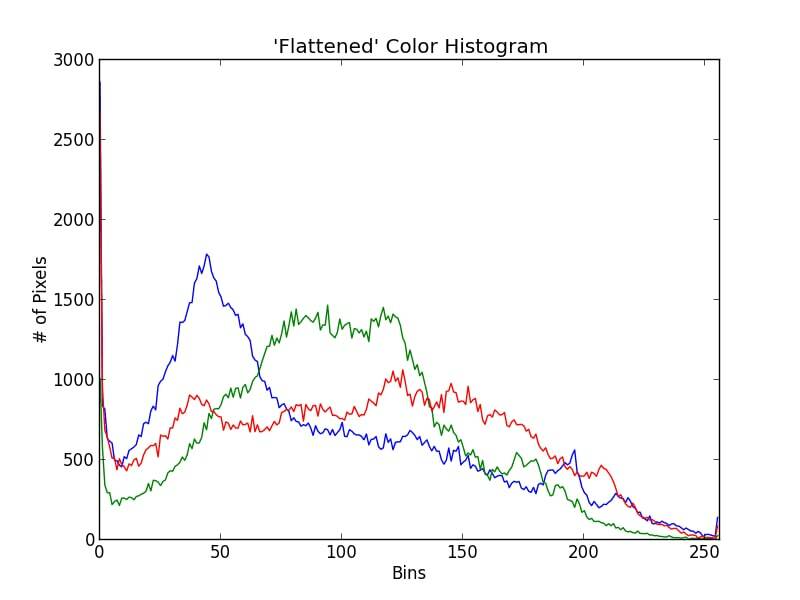

The principle of color recognition is based on working with a histogram of identifiable color components on each pallet of manufactured products. We detect the amount of each color component on the forming pallet and compare it with a reference value.

The QuatroPBC color classifier gives you the opportunity to:

— determine stability of mono colors of manufactured products.If a significant deviation from the standard is detected, the operator receives a signal about the distortion of color characteristics. At that moment, the operator can either stop production and adjust the recipe or operating modes, or attribute the products to another category of halftones within the warehouse accounting system.

— determine presence of different color components in the “Color Mix” products and in products interspersed with colored stones.

When a lack or excess of color components on several pallets in a row is detected, the operator receives a signal about the distortion of color characteristics due to poor mixing of colors.

— determine quality of the mixing of color components

The “Color Mix” products should have relatively smooth color transitions. Materials for products interspersed with colored stones must be well and evenly mixed. All this is determined by measuring the frequency of color change within the process pallet.

If the frequency of color mixing deviates from the standard, the operator receives a signal about the distortion of color characteristics in terms of the quality of color mixing.

— distinguish batches of color products from each other for accurate production statistics.

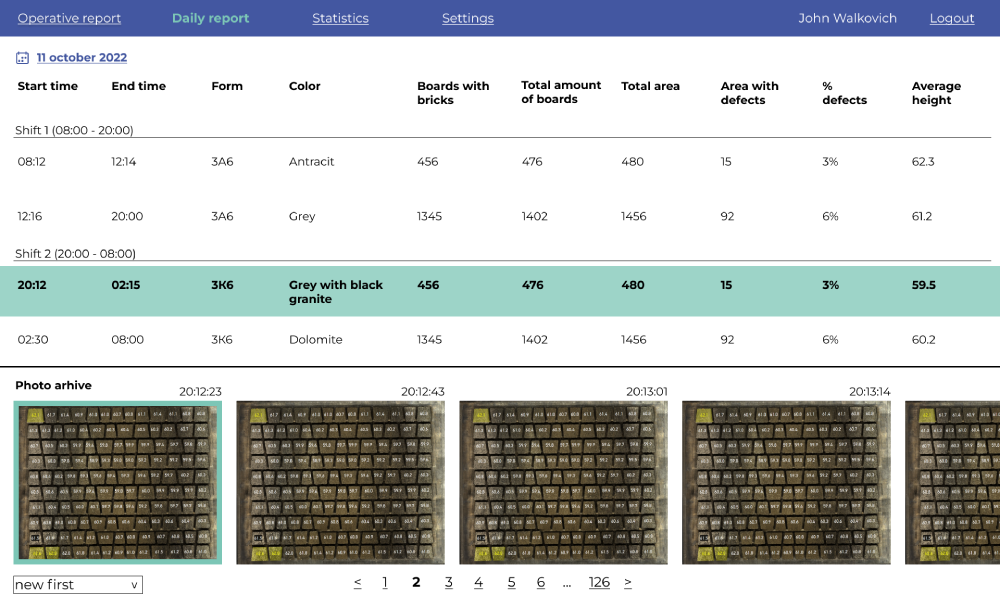

The workshop chief and management can see at any time how the shift worked, which batches were made, how many items were produced in each of them, and what is the percentage of defects in each batch.

This is clearly visible in the QuatroPBC interface. For each batch, the color, the number of cycles, the start and end times of molding, and the percentage of defects are recorded.

The color classifier module in QuatroPBC completely eliminates human factor from the process of the product color recognition. This will significantly reduce the probability of such defects and will increase the probability of detection of such defects. Which in its turn will significantly reduce the cost of processing these defects and of compensation to customers.

The color classifier module is an integral part of the QuatroPBC line and will soon be available to all users of the line in its basic configuration.