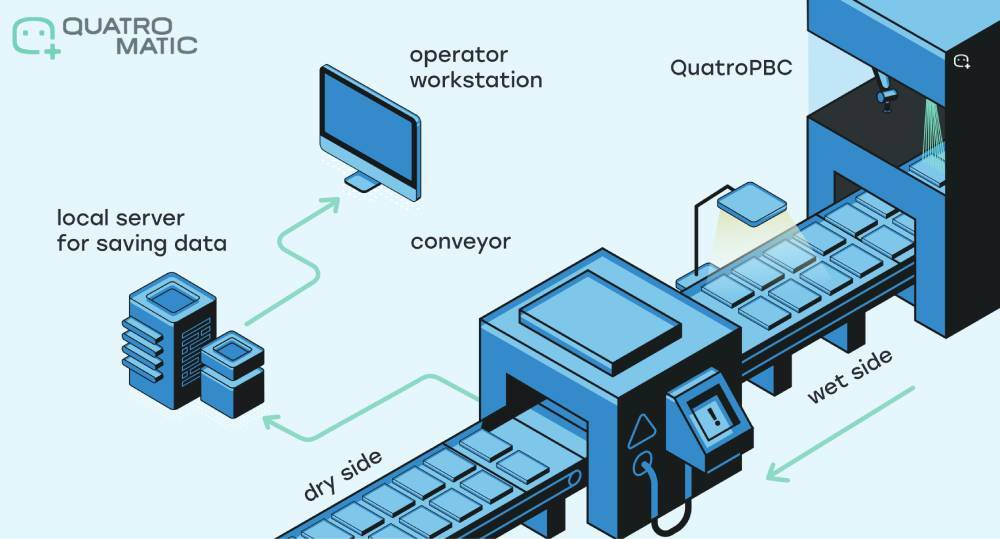

One of the areas of application of machine vision systems is as a part of a conveyor. Camera installed to capture and process images is activated automatically when products pass under it. The camera can be programmed to check the position of the product, as well as the color, size or shape of a paving slab, and can also determine the presence or absence of the object itself in its field of view.

What tasks machine vision solves at a manufacturing site:

- quality control;

- Robot, machine or power tool control;

- testing and calibration;

- real-time production or technological process control;

- information gathering;

- equipment monitoring;

- sorting/ counting of certain objects.

If we turn to forecasts, the continuous growth of the machine vision market will lead to the fact that the most modern manufacturing enterprises will turn into smart manufacturing enterprises and will become leaders in their industry.