Nowadays, any manufacturing requires special approaches to product quality control due to high competition, customer-oriented and cost saving approaches. And although human quality control still prevails in many types of industries, because any industrial enterprise already has at its disposal trained employees and accepted quality standards against which products are tested, one can say that automated quality control based on artificial intelligence can significantly reduce the time of human participation in quality assessment at all stages of the production process.

Machine vision systems are already used in the most modern industries: in the production of mechanical parts, automotive parts and components of printed circuit boards and microcircuits. And they are expanding to more conservative industries - metalworking, the construction industry, production of concrete blocks.

Machine vision in the production of concrete products

Machine vision has made a real technological breakthrough and significantly expanded opportunities of quality control in the industry bringing it to a new, higher level.Currently, the technology makes it possible to monitor the quality not only after the manufacture of goods or products is complete, but also directly during the production process.

This is especially true for the concrete blocks industry, where product quality control is usually carried out only on the dry side. Which means that it is possible to draw conclusions about the number of defective products only upon completion of the manufacturing process.

Installation of machine vision systems on the wet side makes it possible to adjust the settings of the conveyor as quickly as possible and to predict the percentage of the production task completion as accurately as possible.

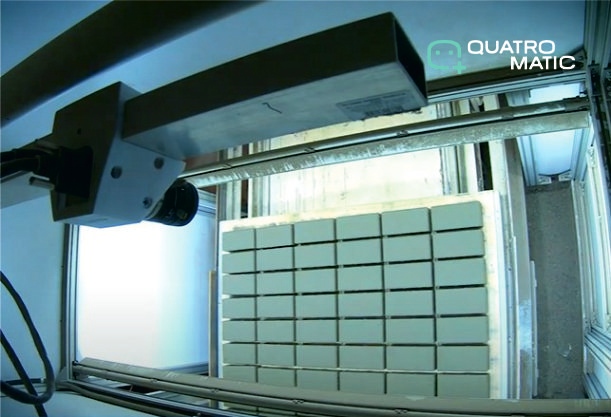

Analysis of the front surface of a tile entails detection of defects in shape or structure, such as dents, cracks, chips, surface imperfections. It requires installation of cameras (to carry-out analysis in the visible range), which in turn requires precise calibration of the cameras and complete stillness of the structure.

Сoncrete blocks manufacturing requires a special approach not only to quality control of products, but also to accumulation of analytics and statistics about all the goods produced at the factory.

This was made possible thanks to QuatroPBC - an intelligent assistant in the production of paving slabs.

For these purposes, in addition to cameras and secure housing, special software is developed and stored on a server that is installed locally at the factory and where all production process data is stored.

QuatroPBC machine vision systems in the production of vibropressed products include:

- "Smart" cameras, i.e. digital cameras that transmit color images, complete with a processor and technical vision software;

- Sources of light, i.e. (special LED matrices and the controller that controls them, fluorescent and halogen lamps, etc.) to illuminate tiles on the conveyor;

- Special purpose software applications for image processing and detection of defects and preset parameters.

The camera detects when the pallet of tiles that is moving along the conveyor is in the position to be inspected. The camera takes a picture of the pallet as it passes under the camera and synchronizes with the light pulse to capture a clear image.

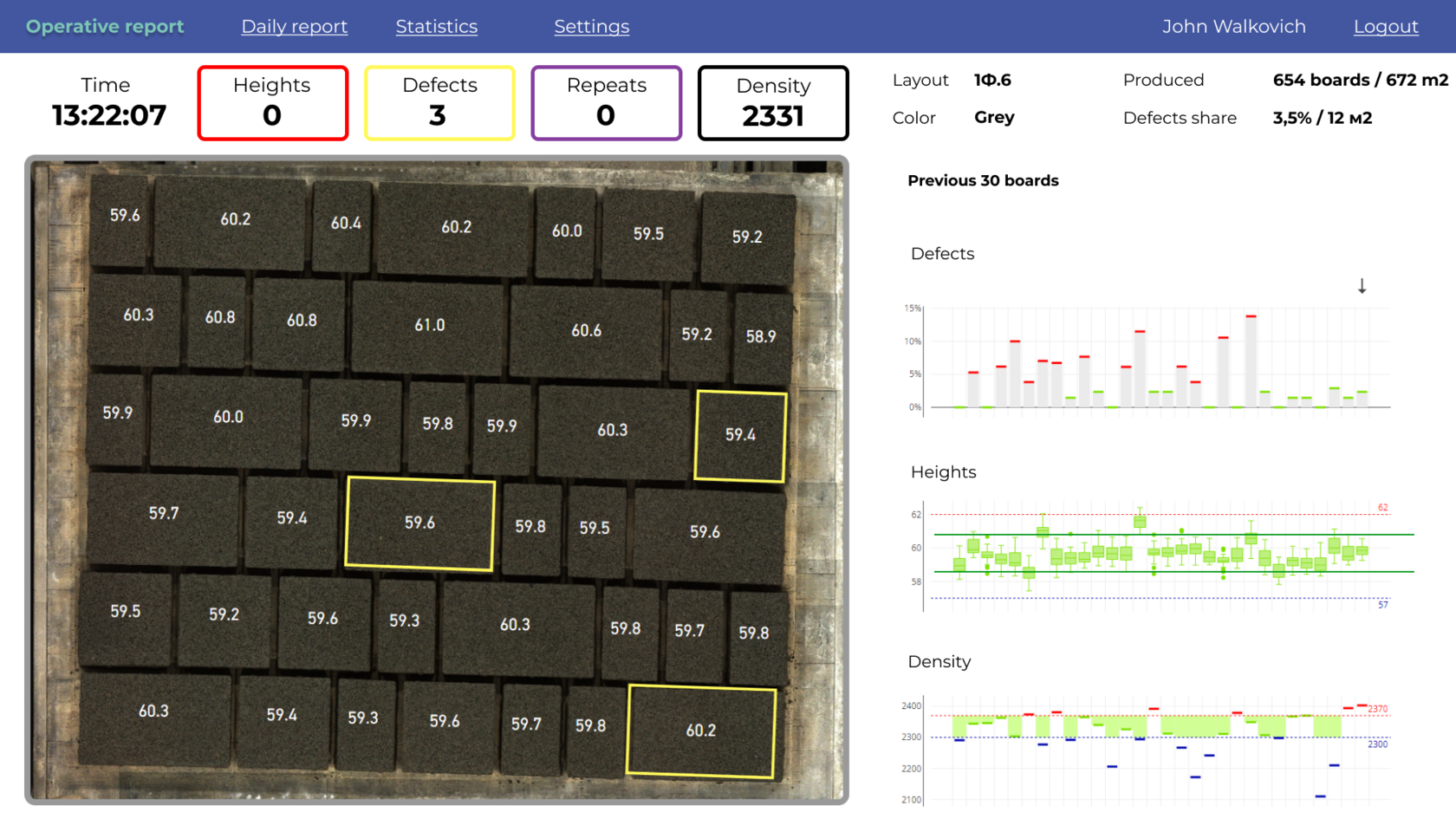

The image from the cameras is transmitted to the program on the operator's computer, where information about each tile on the pallet is displayed in real time.

Benefits of Implementing Machine Vision Systems for Quality Control of Concrete Blocks

Integration of machine vision systems for concrete blocks production does not require changes in the manufacturing process. At the same time, computer vision-based solutions perform quality control tasks faster and more accurately than humans.

Saving time for fault detection of products or raw materials in mass production significantly increases overall labor productivity, reduces costs and makes it possible to more accurately fulfill the production task, which in the long term makes it possible to significantly save on raw materials.

Machine vision systems guarantee that only the tiles that fully meet quality standards come out of production lines and that the quantity of the tiles is in compliance with the received order. Which, in its turn, prevents loading of production and storage facilities with different sorts of dead stock.

Implementation of QuatroPBC quality control system can significantly reduce the level of non-productive losses and overhead costs.

Advances in technology, increased performance, reliability and accuracy of machine vision systems contribute to the rapid and widespread modernization of quality control assessment systems in manufacturing.

Highly specialized solutions such as QuatroPBC make it possible to solve specific problems in the production of concrete blocks.