Neural networks penetrate into many areas of our lives. Manufacturing and production sectors are no exception. Konstantin Panchenko, an expert in the field of neural networks and machine vision, CEO of Quatromatic, has told us more about implementation and use of neural networks in manufacturing.

What the neural networks is?

Neural networks are a mathematical apparatus that is most widely used in computer vision tasks to resolve the following typical challenges:

- detection, that is, identification and selection of objects of interest in an image;

- classification, i.e. attribution of the entire image to one of the classes.

The tasks of detection and classification are basic and interrelated tasks for the operation of neural networks. For example, in order to select a dog and a bicycle in an image, as a rule, the detection task is solved first - we search for all objects of interest in the image, then each object is cropped into a separate image, which in its turn is classified as a dog or a bicycle.

Read more in our article Industry 4.0. The use of machine vision in manufacturing

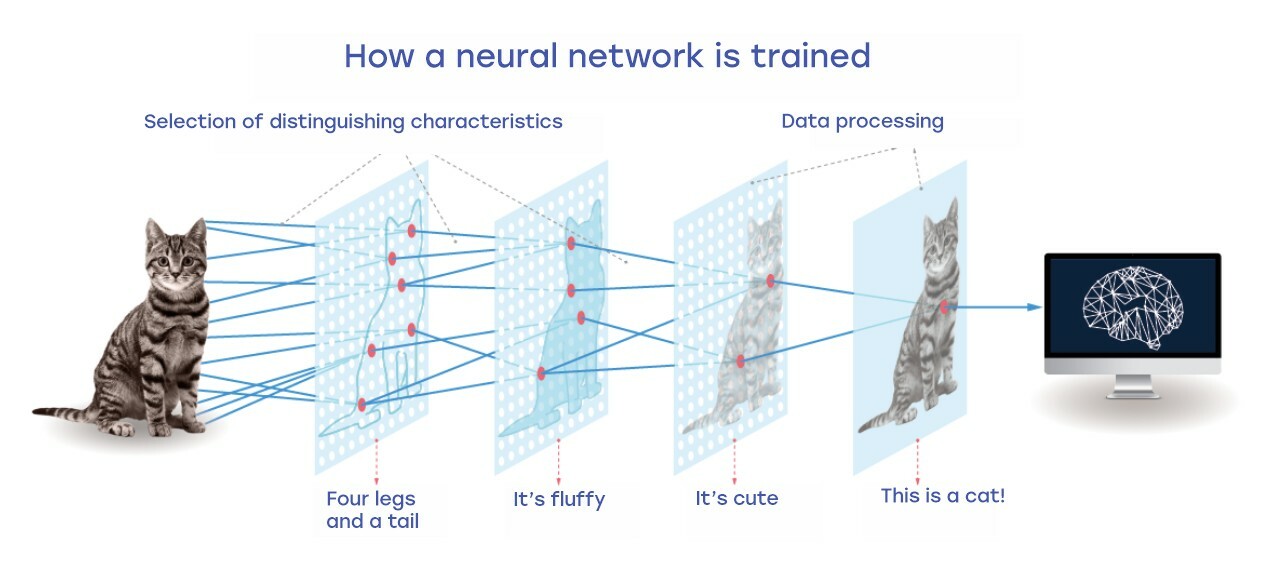

Neural networks are able to independently identify significant features in the data and thus find the necessary objects. The main thing is the correct data set and a large number of training examples.

- detection, that is, identification and selection of objects of interest in an image;

- classification, i.e. attribution of the entire image to one of the classes.

The tasks of detection and classification are basic and interrelated tasks for the operation of neural networks. For example, in order to select a dog and a bicycle in an image, as a rule, the detection task is solved first - we search for all objects of interest in the image, then each object is cropped into a separate image, which in its turn is classified as a dog or a bicycle.

Read more in our article Industry 4.0. The use of machine vision in manufacturing

Neural networks are able to independently identify significant features in the data and thus find the necessary objects. The main thing is the correct data set and a large number of training examples.

A neural network is a machine interpretation of the human brain, in which there are millions of neurons that transmit information in the form of electrical impulses. And if a person can visually recognize objects, then the neural network can be taught to do this. Moreover, the neural network will perform this task much faster than a human, due to the fact that machine vision cameras are much more advanced than the human eye. For example, in one of our projects, we rated the print quality of a yogurt label at 20 jars per second. A human eye simply can’t catch anything like this.

How to use neural networks in manufacturing?

One of the promising areas of application of artificial neural networks today is industrial production. In this area, we see a trend towards production modules with a high level of automation for specific tasks, which requires an increase in the number of intelligent machines. Modern developments give you the opportunity to create customized solutions for different industries and for various highly specialized tasks.

Because modern production is constantly becoming more and more complex, the use of neural networks becomes indispensable for solving such tasks as:

Innovations in the field of neural networks used in production and manufacturing have great potential for manufacturing enterprises all over the world. This is not only and not so much about detecting defects here and now, but rather about collecting big data, the analysis of which can significantly increase production efficiency.

- control of manipulators and robotics;

- product quality control in production;

- ensuring production safety;

- process control: optimization of production process modes;

- monitoring and visualization of dispatching information;

- storage, analysis and processing of information.

Innovations in the field of neural networks used in production and manufacturing have great potential for manufacturing enterprises all over the world. This is not only and not so much about detecting defects here and now, but rather about collecting big data, the analysis of which can significantly increase production efficiency.